A few weeks ago, Junji put a REALLY nice kanna up for sale. My wife immediately told me to buy it, "If you don't, I will!", she said. Here I was, feeling all responsible and prudent for not immediately buying yet ANOTHER Japanese carpenter's plane. Besides, it was too nice, too new. My other tools would get jealous!

Well...... Actually, after seeing me wander aimlessly about the house, sighing heartfully, she finally got exasperated enough to ask, "Why the glum face?". Wisely foreseeing days of excruciating should I/shouldn't I, she decided to be proactive and kill two birds with one stone. I have a birthday coming up soon, and I am one of those people who are impossible to shop for, so she saw the perfect opportunity. Wise AND beautiful!

I have also begun my foray into high quality saws. My personal sharpening epiphany has lead me to learn how to sharpen EVERYTHING that I use. To transform a tool that merely works, into something that feels like an extension of your own hands..... Well, the thought of a disposable tool makes me a bit sad now. But EVERYONE uses disposable blade saws now, right?

Disposables work great, last a long time, AND are cheap. I, of course, need to buck the current and swim upstream. Given the choice between common and cheap over rare and difficult, I unfailingly choose the more obscure. I have been waiting a while for exactly this type of saw, a azebiki-noko, to use for cutting small joints and such. An opportunity presented itself....

A NOS Nakaya azebiki-noko. I think that it is made by Shigemon, but I'm not sure. In any event, it's here and I'm happy.

I need to make a handle.

A bit of surface rust, but no pitting, from sitting on a shelf for 30 years. One side is rip tooth, the other is crosscut.

The teeth are so tiny and sharp, they remind me of the teeth of a fish. A mean little bitey fish!

The blade(plate) is dramatically tapered in thickness. This photo is looking from the heel, towards the toe. It looks like the blade thins into nothing.

The edges are beveled and tapered, hand done. Perfect.

I happen to already have another saw (a 270mm Ryoba) made by the same blacksmith, but a different grade, more machine made than hand made.

Different sizes.....

....same signature.

I had heard about happy saws, and how they will "sing" when being used, how they resonate. The big saw will sing, true, but the little saw...... The little saw rings, clear as a bell, when you touch it. And keeps ringing, like a tuning fork. It's actually a bit unnerving.

This is my first "real" saw, a professional grade tool, and to compare the two saws, side by side, there is little to compare. They are very different. The little azebiki breaths quality. Sharpening is gonna be a b***h, though.

Now, my most expensive Japanese tool, although that's not saying much, haha! For the same price you could buy a (new) very mediocre chisel from Japan Woodworker.

72mm Kojiro hira-ganna (finishing plane).

My first plane that still has its koppa-gaeshi intact, nice and tight.

******EDIT 3/1/2015******

Doesn't this guy read his own stuff? I need to correct some terminology here,sorry. Obviously if you want to learn the proper terms, you might search elsewhere,haha. I suggest

Chris hall.

I said koppa-gaeshi, but that's actually the nearly vertical ledge just in front of the blade's cutting edge.

What I meant to say.......is that the TSUTSUMI is still intact. The tsutsumi is the funny little ledge that contacts the bevel on the primary blade, and is primarily seen on the better quality dai's. After a few years of conditioning the sole of your kanna dai, the tsutsumi dwindles away to a mere flap of wood, but this kanna is virtually new still.

My apologies, my bad.

*****end edit*****

It even came with its own house!

The ura-suki has been carefully preserved, and has probably only been sharpened a few times. I love how easy the back face is to sharpen, when it hasn't been all fouled up. No fat ashi here! Ito-ura, here I come!

The soft iron ren-tetsu is VERY soft, easy to work, and sharpening will be a simple affair.

It also has a lot of figure. I expect that this is a special variety of iron.

The chip breaker blade has a spot of discoloration, where the hot (Yes, hot!) shavings and resin have gummed up the blade.

Sometimes a chip breaker blade will get almost blue from the heat of planing, certainly discolored, and you can feel the heat as you cut certain woods. I would guess that it has something to do with moisture content and all of the heat energy that is released as the water molecules change phase.

The detailed texture on the head of the blade is very deep and 3-D. I almost wonder if it was done using an arc-welder, it looks strangely familiar. It's not something that was done using a texturing hammer, in any event.

The head is a bit deformed by hammer strikes, but not badly.

Not surprisingly, I need to immediately polish it. Notice that I said polish, not sharpen. It IS sharp! And the bevel angle is already right where I want it, 30 degrees.

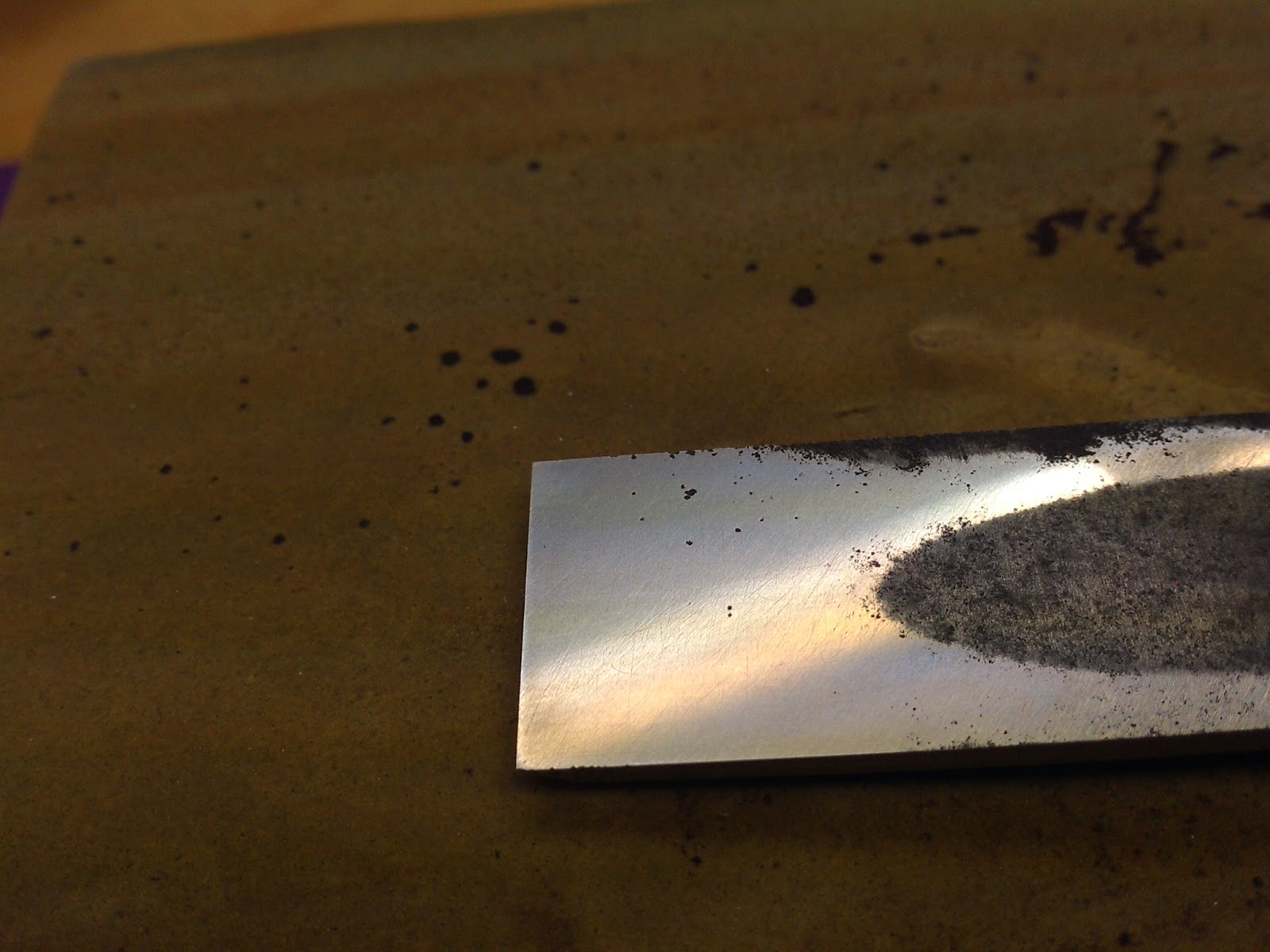

I head right to my best stone, the Nakayama-esque asagi.

Soooo much figure to the iron. The blacksmith used these remarkable materials to achieve this exact effect.....and this is ONLY visible if you use these stones. A true example of a functional synthesis in art, I suppose.

The bevel surface looks dull and uneven, but is actually an almost perfect mirror.

So cool.

AND the super soft wrought iron was easy to repair. It only took a handful of light hammer blows to reshape the head, back into its intended form. This is the softest metal that I have ever worked, by far. I tried to duplicate the original file marks, too.

Definitely my best birthday present, ever. How did you guess?

The danger here is that a door has been opened, a precedent has been set. If I mope enough and let slip some mournful sighs, will she buy me these oh so nice tsuki-nomi that Junji found this morning.....

20-22 inches of giant chisel, meant for fine tuning the supremely detailed joinery used in temple construction. So very pretty, two with ebony handles and what COULD be ren-tetsu bodies (very rare in chisels) and the third just, well......just nice to look at.

Sigh....... sigh.....*ahem*...SIGH!!!