All of these sharpening stones that I have been making, every one needs to be flattened. I have been doing that using various combinations of loose abrasive grit on a flat (ish) substrate. This has proved to be so much faster than, say, sandpaper on a flat surface, that I can't imagine ever using the sandpaper method again. Loose grit is faster AND gets the surface flatter, win-win.

For tools, the choice is not as simple. I have piles of old tools and most of them require fairly substantial reworking. This means removing lots of metal, and even *I* get tired of grinding away for hours on end, at least if the time/work curve feels painfully flat. I do use power tools, grinders and the like, but I prefer handwork, IF the T/W curve is reasonable.

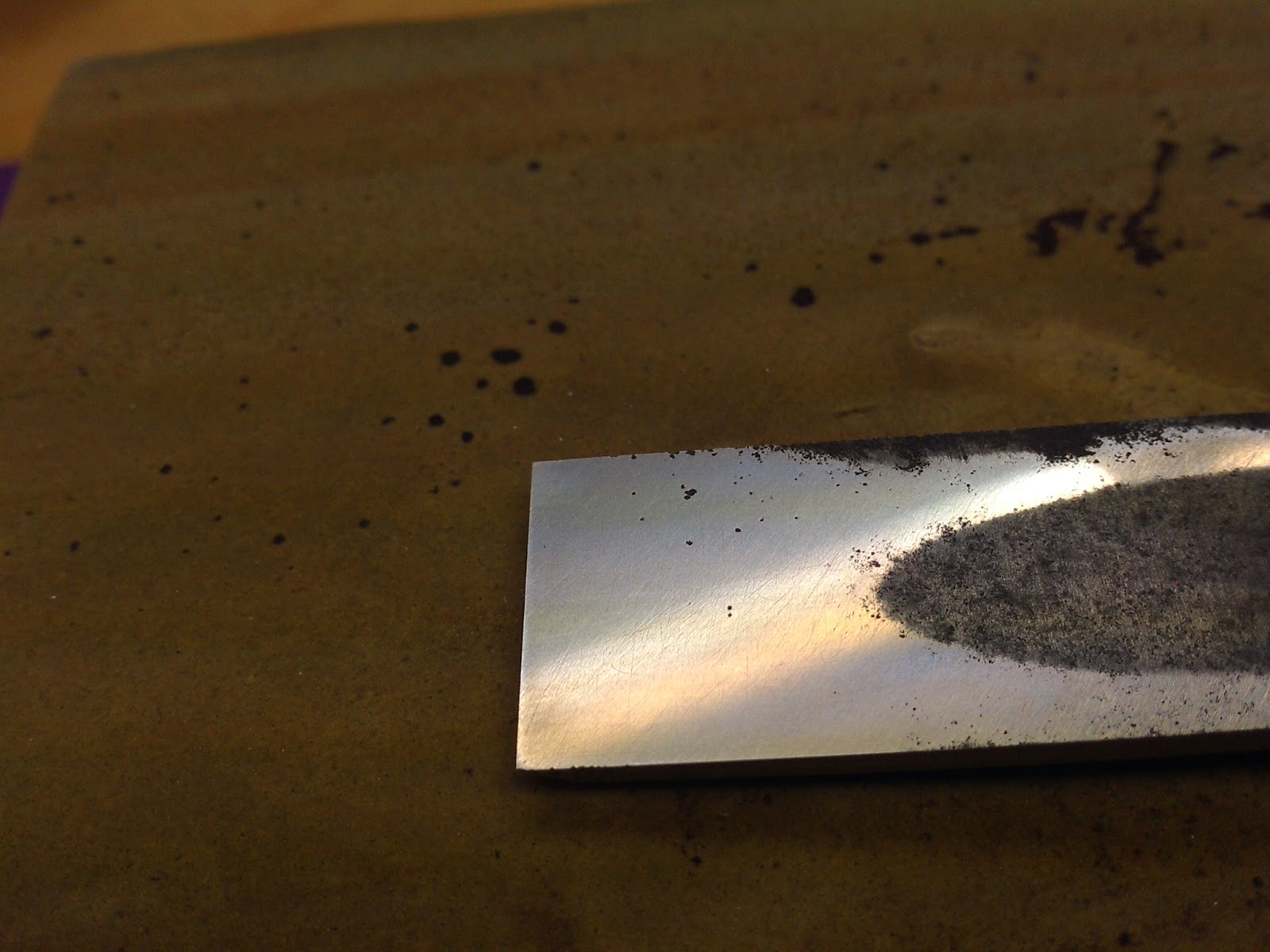

I am going to be trying loose diamond grit on a lapping plate, but for now, I just want to make some surfaces flat. I have been using a flat granite tile and valve grinding compound....

.....but the level of wear is unacceptable.

This was after only about 12 blades (2 were amazingly hard, though).

So. Diamond stones. The hand sharpener's Crack cocaine... And they are flat, right?

Two stones, a DMT duo-sharp and an Eze-lap #600 grit.

The DMT I bought new, about 1 year ago. The Eze-lap is from my friend Brandon, and is old, 10 years? 15? It has seen some use, definitely. The Eze-lap (10 years old) works great, but the DMT (1 year, maybe) is getting decidedly tired, and is also starting to delaminate.

It's also bowed +1/64 along its length. Always has been. Many people have found this to be the case, particularly with the perforated composite stones.

Significantly bowed, for what is widely advertised as "very, very flat". The company that makes the DMT'S advertises 0.001/inch for their regular bench stones, and supposedly BETTER for these duosharp stones. 1/64 over 8" = 0.00195, almost double the target 0.001. Decidedly bowed.

The problem with the bowed sharpening stone is this. Say that you begin with a flat blade. Using this stone, you will make your blade first concave (#600 Fine), then convex (#1200 Extra Fine). Then you have to flatten the blade all over again using your finishing stones, which takes a while. All told, you have removed about 4X more material than you would if you were using a TRULY flat stone. I like sharpening things but......

The Eze-lap is usably flat....

....but that's because I made it that way.

A BIG vise and LOTS of pressure, these are made from hardened steel and are very sturdy. You can see that my little fulcrum block is crushing. I had to use two hands and extra ooomph! to tighten the vise, just shy of needing a breaker bar. Very sturdy! I obviously can't do this with the DMT, bummer.

Worse, however, is the scratching. The DMT has #600 (F) one side, #1200 (XF) on the other. The #600 (F) is consistent in it's degree of aggressiveness, but tired. The #1200 (XF) side is very uneven, with approximately half being an appropriate #1200, while the other 1/2 feels more like a #400 grit AND has a few random, huge particles, just to keep things interesting. I'm starting to wonder if I got a bad one......

At least I finally found out where my mystery scratches are coming from. I get these scratches on every tool that touches the DMT, and they take RIDICULOUS amounts of time to remove. Heck, this thing even left scratches on my sharpening stones, before I figured things out. Now I try to use stone/stone to true my sharpening stones. You need to use a DIFFERENT diamond stone to remove the scratches left by this stone, far from efficient. Ergo, the Eze-lap stones.

The two stones use different types of diamond grit. The DMT uses a mono-crystalline diamond abrasive that they say is better/more expensive/higher quality/longer lasting etc. The DMT does leave a nice, even scratch pattern, at least on the #600 side.

The Eze-lap #600 uses poly-crystalline diamonds and though old and worn, still is MUCH faster than the DMT, although the finish isn't quite as fine. This is consistent with other people's findings. You can read a bit about the mono/poly debate in various venues, written by people with WAY more experience the I.

Like this one....

sawmillcreek. Synthetic-polycrystalline-diamond-paste-cheap-and-otherwise

The consensus is that mono starts fast, wears out fast, and produces occasional large scratches. They are more expensive, too. Sounds familiar. My $8 set of (not so)crappy Chinese diamond stones are still working fine, even though they get abused on a daily basis. They are most likely poly diamonds. Seriously, just today I did the rough shaping of an old kanna blade, worked on the initial flattening a MF'ing hard potential sharpening stone, chamfered the edges on another stone, sharpened an old Japanese ax, and (finally!) worked a bit on flattening a cast iron lapping plate.

I am going to send my DMT in for evaluation. I'll let you know how that goes. Today, I would give 5 DMT's for 1 old Eze-lap. Maybe 7. Probably not 10, though. I mean, it DOES still work. I have read that some of their other products are more consistent in the lateral plane ie: Dia-flat lapping plate @.0005/inch.

Kinda spendy, though.

Update 4/11/2014

I sent my DMT back to the manufacturer for evaluation last week and they promptly sent me a shiny, new replacement (+promos!) Yay! They even had the flatness verified by QC before sending it out the door. The replacement is within specs, so I'm satisfied.

What I find more refreshing is that the company stands by their product (made here in the USA, BTW) with a very simple policy. If it doesn't meet your standards, they will replace it. It's that simple. That commitment, plus a good level of attention to detail is commendable. I wish that this was the norm, rather than the exception.

Eze Lap sent me a NEW 2 1/2" X 11 3/8" 600 grit stone for free when I phoned them about resurfacing the one I bought in 1986. They didn't even ask for the old one back! I have all the grits now in large size and love 'em. I sharpen knives now professionally having retired from fine woodworking / fine finishing after 42 years.

ReplyDelete