Treads in the works.

And.... A gift, for a friends collection, a seme-ganna.

At long last, here it is.

From this......

.... To this

I would like to tell you about how difficult this project was, all of the interesting little details and tricks that make these projects so gratifying, but......

This was super easy. A light surfacing, to remove the ubiquitous red Japanese paint (My friend Brandon says that every old american tool that he buys has spatters of white paint on it. The Japanese tools that I buy have red. Huh, Go figure!), left the wood looking wonderful.

There was some iron staining around the mouth (What have you been eating?!!) and top of the dai. This is simple to remove, using a phosphoric acid solution, typically sold as a paint prep for rusty metal, or an etchant/cleaner for ceramic tile. Swab a little on the dark areas and it will fade away in 15-30 minutes. The acid is very mild, no worries (I mean, don't drink it, or anything, but...), and doesn't discolor the wood.

The irons were a pleasant surprise. They are virtually unused, and only required a minimum of attention. I gave them a brief traditional rust bluing, to even out the slight amount of discoloration from the surface rust.

The surprise was that the main blade was forged from ren-tetsu wrought iron (unusual for this size of blade), and even more surprising was that the sub-blade is laminated as well (definitely not what I was expecting).

|

| Notice the dinged up corners? |

The ren-tetsu is very nicely layered.

Unfortunately, as I was removing the blades to photograph them, haha! Dropped!

At least we know that the hagane isn't brittle hard, eh Michael?

So, off to the stones for a very quick touch-up. This was done rather late in the evening, so I did this old-school (no power, just muscle).

My stone sequence for this quick project.

Two cheap China diamond stones (mounted by me on wood bases), a strangely discolored white aluminum oxide based man-made waterstone (probably a King Hyper, and rapidly becoming a favorite of mine), and two naturals to finish things up.

The stone on the left is an aoto of some sort. It is relatively soft and serves to ease the transition, from the deep angular scratches of the artificial stones to the shallow, gentle scratches of the natural finishing stones.

A quick way to evaluate the relative hardness/softness of a natural waterstone, is to dab a bit of water onto it's surface. The softer stone quickly absorbs the water, while the hard stone absorbs little or none.

The choice of a hard stone versus a soft stone is rooted in some very interesting physics. I'm not going into that now, but it's something that I am trying to get a better grasp of. Later....

Because I mucked up the blade pretty well when I dropped it, I need to flatten the edge first, using a diamond stone.

The newly flat edge is uneven, because the blade had been partly skewed. In for a penny.....

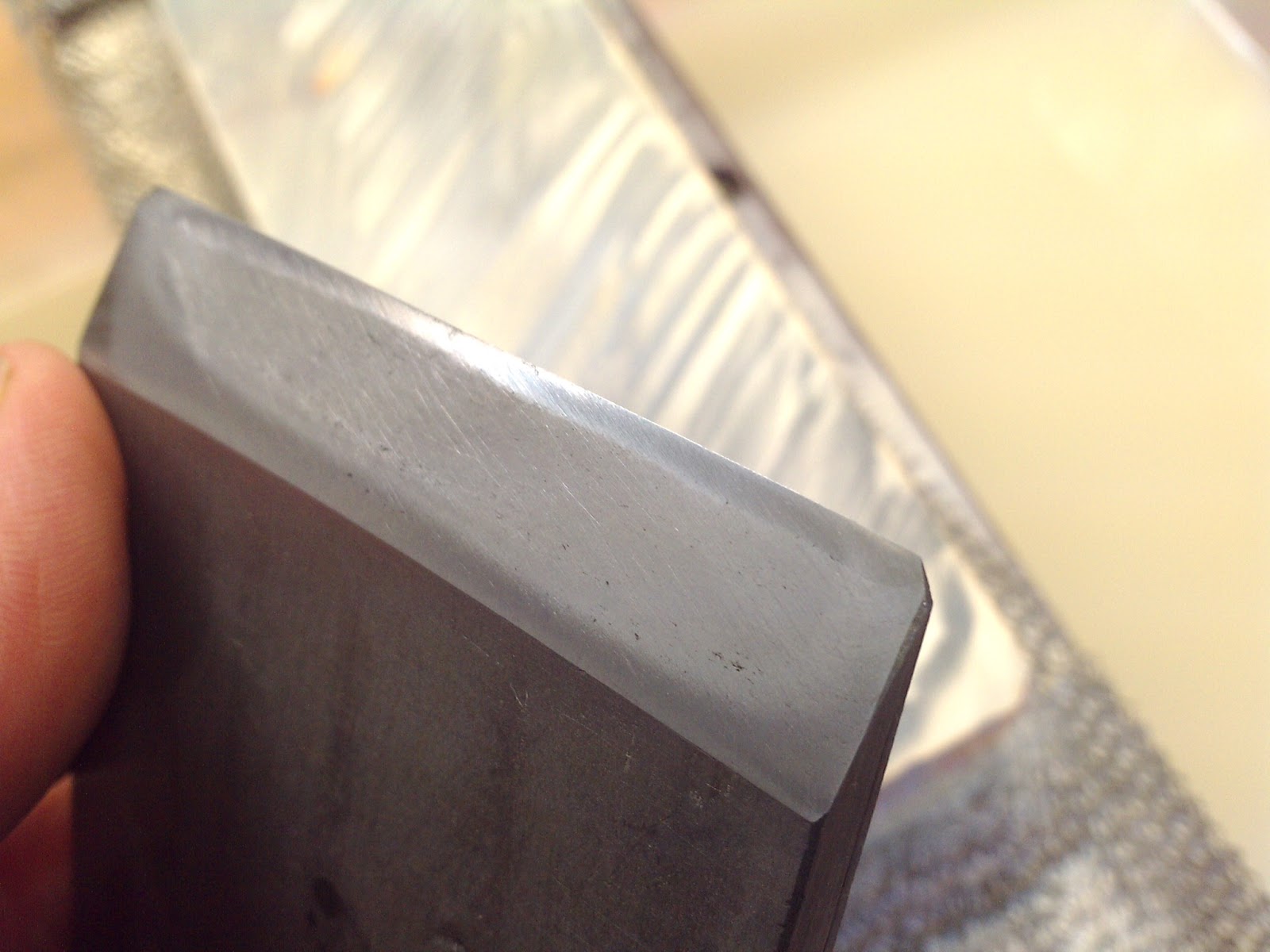

I reset the bevel, using #80 grit 3X sandpaper (a 3M product), mounted on glass.

Yes, that is a sharpening aid! I'm feeling lazy. They aren't worth a crap for Japanese plane blades, but for narrower stuff they can be damn handy.

Instead of letting the burr form and fall off on it's own, I have begin removing it as I go, using a fine grit stone.

It takes a few moments longer, but *maybe* provides a stronger edge. We'll see. My thought is that the burr falling off on its own, is due to metal fatigue, and work hardening is not what you might choose for a durable edge. This idea isn't original I'm sure, but it is something that I want to try it out.

The hard Ozuku asagi gives a really nice finish to most blades, and is one of my favorite stones. You can really see the beautiful layering pattern in the wrought iron.

This blade is also a bit unusual, in that the stone gave the wrought iron a bit of a purplish cast. Every one is different. I love it!

Very close to a full mirror polish. It's funny that these cameras make it so difficult to for me to get the photos that I DO want (I want a macro shot of the layered jigane), but give me many pictures like these.

Here is where those stair treads are going. Obviously a closet (at least, it was.).

Thankfully, there is ample feline supervision in our house.

Cat tested.