More about making a kiln to produce blacksmithing charcoal.......Installment #1 here.

OK, where was I?

I toss on a few more sheets of tin to serve as a roof and it's time to give it a try.

I first lay a perpendicular floor of sticks, to keep the wood slightly elevated and to give an air path for the initial stages of burning.

I fill the barrel with short 15" lengths of cut Guava branches, trying to fit them as tightly as possible. Here's half full.

Now, as tightly as possible might not be the best choice, but being the curious sort that I am.........

See, the problem is that:

- The insulating grass/mud mix is wet as hell still, and will likely never dry completely, given that it rains here so frequently.

- The sticks that I am coaling were cut 6 months ago, but have been sitting out in the elements. They are far from being dry.

- By nature, I am sometimes perversely contrary (just ask my wife), so what the hell. Fill it to the brim! Bring it on!!!

I've got two remnant circles of roof tin staring at me, so I trim one down to fit inside the barrel, forming a baffle. Notice that the corrugations run vertically and there is an air-gap at the top of the divider. I want about 2" of clearance between the baffle and the very front of the lid. Hopefully that will be doesn't restrict the airflow too much.

I had cut an 8" square opening on the lid, three tabs that I bent over to give rigidity to the thin steel.

I also built up a soil platform to get the firebox up where it belongs.

I bent a small sheet of tin into a box-like shape that will serve as the firebox. I support the tin with dirt, rocks and bricks, whatever is close to hand.

I forgot to take pics, but it's nothing special. This is an area that I want to improve some. V#2 will probably be a rocket stove variant. More on that to come....

Grab a healthful breakfast of leftover seaweed salad, snag the fire extinguisher and the propane torch and......let's see what happens!

We've got smoke! The white smoke phase is relatively cold, and nearly all of the smoke produced is water vapor/steam. The guava that I'm burning smells nice, just perfect for smoking meat!

You can see that I've got a chunk of broken CMU restricting the opening at the front of the firebox. You need to balance the amount of air that gets to the fire, enough air for combustion, but not so much that you lose the draft. It's tempting to build something fancy, but I'll think about that later.

For a baseline measure, the firebox is at 200F.....

....and the lid temp is 236F.

The all important stack temp reads 134F.

I'm psyched, the 134F means that hot air is being drawn through the tightly packed sticks, no problem.

The amount of time required to convert a drum full of wood into blacksmithing charcoal will vary. I started this burn rather late in the day and given that I packed the kiln full to the gills with only superficially dry wood, leaving little room for air to flow, this batch should take quite awhile. Between searching out dry twigs to get the fire established (you'd think I'd have a pile of already dry wood set aside, wouldn't you, haha) doing dishes/laundry/cooking dinner, changing the brakes on my car and ten other things......6 hours later it was getting dark, right when the kiln really started pumping out the smoke. Bad timing, because the nightime's cooling air will hold the smoke right at ground level. I capped the vent stack, blocked the air intake, then called it a night.

The next day the fire was much quicker to take, given that the wood in the kiln was now partially cooked. The stack was pumping white smoke for a good hour before the color of the smoke began to shift to the yellow. The yellow smoke phase is the nasty part of the process, as this is when the more interesting volatile compounds are being released from the wood. The yellow smoke stinks, plain and simple.

Your neighbors won't thank you for this.

Is it any wonder that I need to live in the country, haha?!

As I mentioned before, the yellow smoke is volatile, and quite combustible. Clever people channel the smoke back to the burn chamber and harvest those otherwise wasted BTU'S, but this is right about the time where the process starts to speed up, so extra heat isn't what's needed. Still, my sense of economy is offended.

People ask whether you can just burn straight wood in the forge instead of charcoal, and the answer is yes, BUT.......All of that white smoke we saw is water vapor that pulls huge numbers of BTU's from your forge, so a straight wood fire isn't very hot. Also, the yellow smoke is exactly what you get from a smoldering fire, virtually guaranteeing that everyone you meet will ask if you were recently at a bonfire party. Sure thing, the smoke goes right in your eyes and because the wood burns with a visible flame, you'll be doubly blind. In comparison, good charcoal burns with a nearly invisible flame, gives off almost no smoke and very little scent. Apples and oranges.

The yellow smoke phase sees elevating temperatures everywhere.

I love the double wall vent pipe. Warm to the touch, that's all.

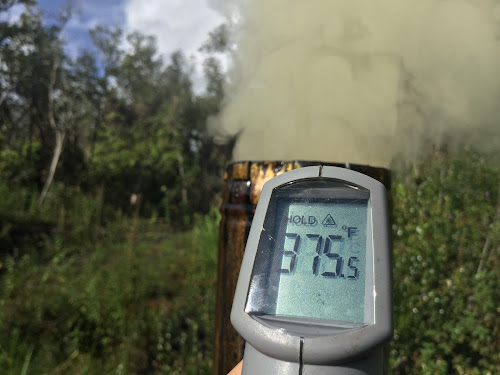

And the vent gasses themselves.....nearly 400F.

So, things start to happen more quickly now and it's time to be attentive. From yellow smoke to finish took about 1.5 hours but again, this was wet wood, packed tight. A loose or cross stacked pile would produce only 1/2 the amount of charcoal, but might only take a few hours if you use dry wood.

1 hour or so of billowing yellow clouds of smoke, but now the smoke is getting thinner, less yellow, more gray.

You see how the air is getting clear, right where the gasses exit the stack?

462 degrees Fahrenheit.

Remember my clever grass and mud insulation? That's not just steam from it drying out, haha.

117F is great, but that's due to the insulative effects of the lava. The grass has turned into char, and the only reason that it didn't burst into flame is that the lava cinder kind of smothered it, deprived it of air. More clay might have helped, but the drum temperature gets extremely hot, so maybe straight dirt/rocks is just the way to go.

You need to have *some* flame pics, right?

Once the draft is established, nearly all of the flames and smoke from the heat fire get drawn into the kiln. The flames hit the baffle then travel up and over. I assume that by that time there isn't enough oxygen to support true combustion, just what we want. You can also see how wet this wood is. I'm actually surprised that it burns this well!

Another 15 minutes goes by, and the flue gasses are even more clear. Almost all the water and other stuff has been expelled from the wood.

Almost 500F.

Another 10 minutes, gasses are clear at the exit, and the smoke is developing a distinct bluish cast. Almost done.

Almost 600F, a rise of 100 degrees in just a few minutes time.

5-7 minutes more and it's time to shut it down. There volume of smoke is drastically reduced and the smoke exiting the pipe is blue, not gray.

Almost 800F.

I pull the firebox away from the mouth....

...and pile up some bricks and dirt to shut off the oxygen. I cap the vent using an old coffee can topped with a rock, should the breeze kick up.

Tomorrow I'll open it up.

Fun, right?!

looking forward to tomorrow's post. It really looks like fun, makes me want to move to the forest.

ReplyDeleteThe rocket stove plan is genius! Very clever. I can't wait to see it built.

ReplyDeleteCan you post some sketches of the design or links to your inspiration?

You really know how to build the suspense, I'm very excited to see how your first run turns out!

ReplyDeleteCool! I can hardly wait until tomorrow's post. I'm hoping the guava charcoal works even better than softwood. You have an almost unlimited supply.

ReplyDeleteHaha, you guys are funny! It's so kind of you to pretend that this charcoal stuff is interesting and suspenseful,.....oh wait!.....I DO love this stuff! Brandon knows it for the truth, having watched me obsessing over my charcoal, more than anyone else.

ReplyDeleteI'll finish up, as soon as my freakin' pics upload. Ipad to Google photos was bad enough, but now that the new iOS 9 came out, it's basically a standstill......Ugh, can't wait to go back to Android. If not for the totally awesome iSight camera on this thing, I'd chuck it out the window.

Ryan, the closest thing to plans and schematics are linked to on the first post, this being essentially a Iwasaki charcoal kiln. Here is a YouTube video that is very close to what I ended up building...

https://m.youtube.com/watch?v=xchk4ufYAAE

....the difference being that I added the internal flame diverted baffle in my design, sort of a cross between the kilns in the video and a proper Iwasaki kiln. My next improvement will be to reconfig the firebox into a vertical self feeding, rocket stove kind of thing. I guess it fits the pattern for being a rocket already, though that's more by accident.