|

| Wrought iron kanna blade, nicely forged (not by me, ha!). |

I am working feverishly to improve my forge welding abilities (to little effect, it seems at times), emulating the style of blade construction that I admire so much. Hard steel/soft iron. For hard steel, I have been using old files (Nicholson, Simmons, Heller etc). Finding that stuff is easy. The trick is finding the soft iron.

Most of the soft metals that I have found are considered "mild" steel, with a carbon content of <0.40%. While this material doesn't have enough carbon to achieve a serviceable, durable edge, it DOES harden a bit after quenching. One of the beauties of a hard steel/soft iron blade is that it results in a combination that is easy to sharpen. Harder iron means more difficult sharpening. I want SOFT iron!

The gold standard of soft iron is "wrought" iron. Real wrought iron isn't commonly available. It has not been produced commercially for something like 50 years now. I'm not talking about "wrought iron furniture" type iron.

|

| The Eiffel tower is made from REAL wrought iron (thanks Wikipedia!). |

|

| Home Depot wrought iron isn't. |

This is almost always mild steel bent and welded together to LOOK like true wrought iron. I want the real stuff.

The trick is finding true "wrought" iron. I had decided that I wanted to start working with this material a few months ago, and have been looking ever since. How do you find this stuff? What do you look for? Is it actually THAT rare?

Just the other day, literally minutes before pulling the trigger on some salvaged wrought iron from a seller on eBay, I found a VERY rusty piece of metal, half buried in the yard. Our house seems to have been built on top of a garbage dump, so this wasn't that unusual. Uncovering random junk, that is. It could be worse..... At least it's not built on top of an Indian burial ground ("Poltergeist" anyone?).

I forgot to take a photo of the metal in its "as found" condition, but it looked like your average rusty junk. At the same time, my daughter found another chunk of heavily rusted steel, about 10' away. Wrought iron?

The only methods of field testing that I've found for distinguishing between "real" wrought iron and ordinary mild steel, are three:

- The bend test. True "wrought iron" has a typical (stereotypical?) stranded or fibrous appearance, at least when bent, then broken. Sometimes the exterior surface has a bit of a wood grain look. Notice the "stranded" appearance of the break?

|

| For sale, http://www.oldglobewood.com/real-wrought-iron.html |

2. Spark test.

|

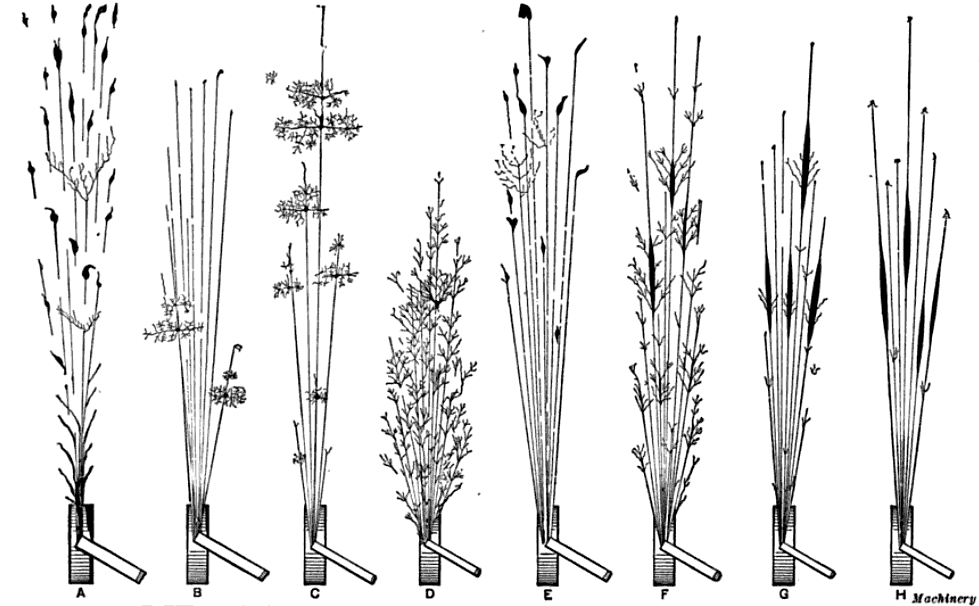

| http://en.m.wikipedia.org/wiki/Spark_testing |

3. Acid etch.

A quick swipe with ferric chloride brought out the character in this kanna blade.

Simple, right?

|

| Laminar corrosion |

Severely corroding metal sometimes exhibits a peculiar form of corrosion, termed "laminar" corrosion. I used to see this form of degraded metal underneath my car, acerbated by the conditions inherent to a Midwestern winter. This type of rusting can look very stranded, a bit like wrought iron.

To my surprise, both pieces of metal forged just fine. That was interesting, but of even more interest, was that one piece (the one that my daughter found) was MUCH softer than the other. The chunk of rusty crap that I found worked about like any other piece of steel, but the soft one she found worked like butter, well..... More like clay maybe. Really nice, though!

Wrought iron has a reputation of being difficult to work, at times. You are supposed to work it at a very high heat, nearly the same temperature that you use for welding. If you work it too cold, it can start to fall apart, unravel almost. This is due to it's filamentous nature.

I forged this down hot, to see if the metal would split once it got too thin. It didn't, so I hammered it out flat, but cold. It shows very good integrity, better than mild steel actually. It reminds me of working copper. I soaked the sample in ferric chloride for an hour, getting a slightly mottled look towards the tip, but nothing like my kanna blades show (and that only takes a few seconds).

I tried the "break" test. The soft sample is on the left, the harder is on the right.

Neither sample exhibits the characteristic "broken stick" look of wrought iron. The picture was taken after the samples had been out in the rain for a few days, resulting in some surface corrosion. See how much cleaner the sample on the left is? Weird!

We also found a rusty nail in the yard (imagine that!). It also forged well, felt soft, and the break looked a bit fibrous.

So, is this stuff wrought iron? I don't know. What I do know is that it is a really nice material to work with.... and I want more!

I am on the same journey of discovery as far as finding wrought iron in the wild turns out I had to look no further than my barn

ReplyDelete