Another eBay fail......"I've lost my Mojo!!"

Here's the original description.

Offered for purchase

ONE

Old Natural Very Fine White Sharpening Stone. Measuring 8 1/16" long, 2 9/16" wide, 1 1/8" thick, and this weighs 1 lb 14 oz unboxed. Not signed as to the maker. This is in decent shape, the only cleaning I did was to give it a quick wash with soap and water. There are some chips on the corners and a few small ones on the edges. There is some rust staining on the sides and a few on the top. The one face has a wee bit of a dish end to end, the other one looks fairly straight. There are a few light dings on the face but nothing too bad. This one ain't perfect but it sure is old. A decent collectible old sharpening stone for sure!

Not a bad description, compared to most of what you see on eBay. Natural, white, and old...... I was hoping for a Hindustan or maybe a Lily White Arkansas/Washita.

Not natural, white, or old. Well, it's actually pretty white....for a sharpening stone.

So what is this thing?

The size is a direct match to my "King" brand Deluxe #1000 grit.

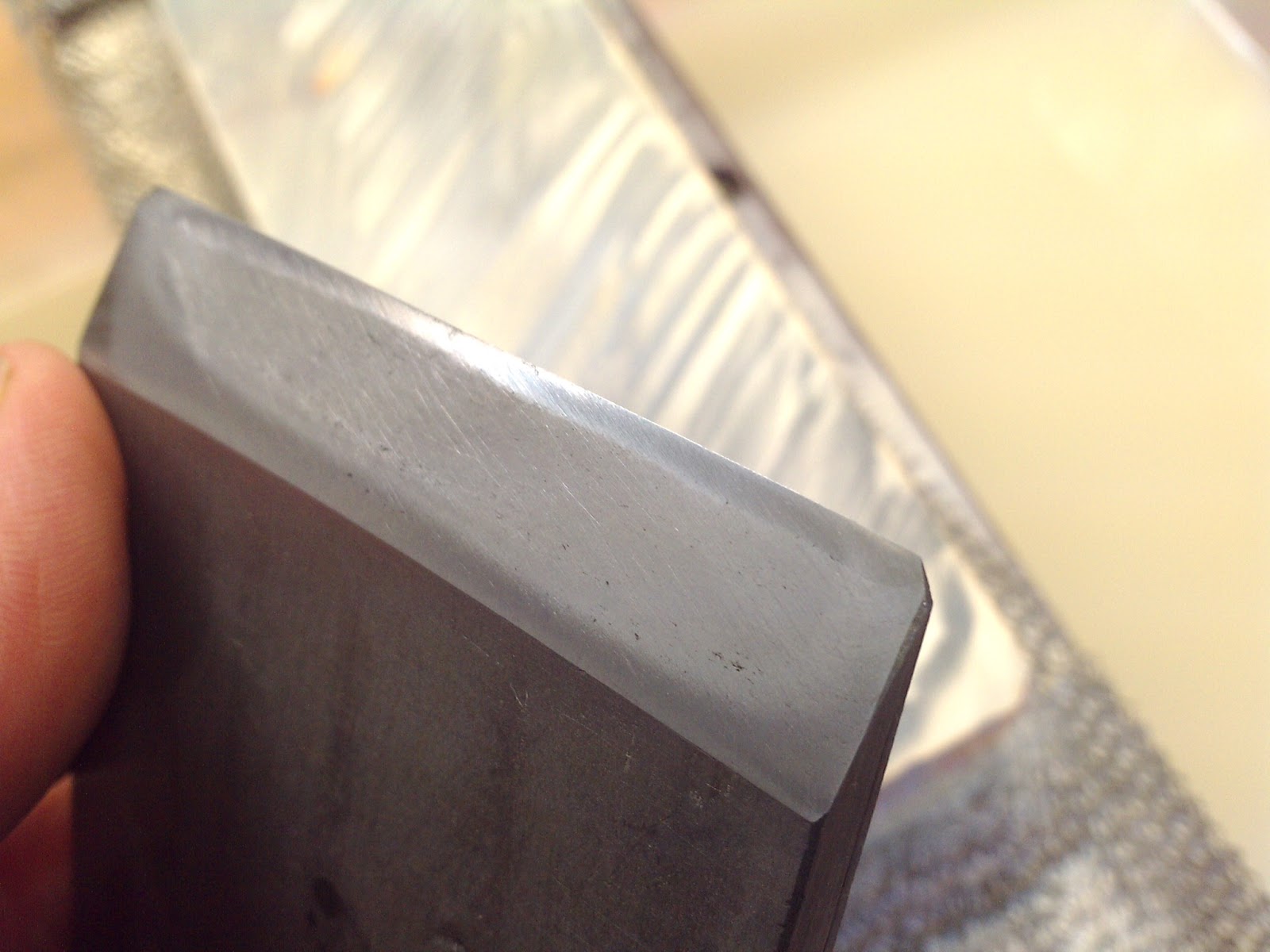

The corner shows some raised vertical lines, extrusion marks or molding imperfections.

Faint horizontal cracks, signs of shrinkage (There was shrinkage!!!). Again, sure signs of a man-made stone.

I sent the photos to the seller, but he still maintains that it is an old, natural sharpening stone. He did begrudgingly offer a refund, but I would need to open a complaint case with eBay/PayPal to get my shipping refunded...... How do you get a 100% rating on over 11,000 tool sales, and not learn something about old sharpening stones?

Well, enough bitching.... my curiosity got the better of me, lets see what this thing will do!

What's a big Norton oilstone good for? Flattening waterstones, haha!

Actually, they work fine for the simple carbon steel used for old western tools. I support the theory that tool steel hardness matches the available sharpening technology. You can achieve an Rc-64 hardness with simple high carbon steel, but it will be brittle and you won't be able to easily sharpen it using traditional oilstones. To draw the temper down to a more realistic Rc-56/58 is practical. The blade become more tough, resilient to impact shock, and is easily sharpened. What good is a super hard tool that you can't sharpen?

My point is that it's not that they didn't know how to make hard steel blades, back in the day. To the contrary, it's that they were smart enough not to. Your average 18th century carpenter is going to be pretty pissed-off getting a blade that shatters the first time he hits a knot in the board he's planing!

Culturally, we have the unfortunate tendency to discount and discredit the knowledge of the past, assuming that "They just didn't know better". Don't get me wrong....I don't assume that everything old is better than the new stuff. I think that it is very important to study "HOW" things were done, because the "WHY" is still pertinent today. If you assume that you're the only smart guy in the room, it makes it hard to learn anything new.

****

Where were we? Oh yeah.....

This face I flattened completely. Underneath the old, soiled surface is an extremely smooth, ivory white (not pink, like in my crappy photo) material, most likely of an aluminum oxide composition. Some staining remains.

This big naga-dai (big-body) kanna has been sitting here for too long. This is the equivalent to a western jointer plane, like a Stanley #7.

Before

After 15 seconds or so.

I'm just looking at scratch patterns here, not trying to actually sharpen, OK?

The stone feels only slightly gritty/coarse, different from my King #1000 grit, smoother and moderately muddy. Fast-ish.

Now to compare it to what I do know.....

The suehiro #3000 is way finer.

The King #1000 is..... different.

I run this one so that the scratch pattern runs parallel to the edge....

.....then a few swipes on the new stone to see how the scratches compare. The white stone scratch pattern runs about 50° here, with the #1000 visible underneath and parallel to the edge.

They look about the same to my eye. The character of the scratches looks slightly different, though.

Now I do a side-by-side comparison. The red #1000 grit on the right, the white stone on the left.

While I would guess that the new white colored stone is close to a #1000 grit, the scratches have a different look to them. The red #1000 (right) shows lots of coarse marks that extend to the hard steel. The scratches from the white stone don't extend into the steel so much, indicative of a softer abrasive, perhaps?

Artificial waterstones are composed of a range of grit sizes to achieve a nominal finish number. The old-school Kings use a broad range of grit sizes because, for 80% of users, you just want something that is fast, but still inexpensive. The vast majority of users are sharpening knives, and these stones will give a good serviceable edge. Sharp, yet toothy enough for meat and soft veggies. There is also the thought that big scratches and little scratches can be beneficial arrangement, resulting in a more durable edge. Interesting, to be sure.

The white stone may have more finely graded particles but it feels faster than the red, on this relatively hard blade. One thing WAS apparent...... This white stone is much more resistant to dishing than the King Deluxe.

The King Deluxe #1000 grit was pretty dished after relatively light use, although this blade was fairly hard.

The gap measured 0.06" over 8" -or- 0.15mm over 205mm, take your pick.

This is the white stone, zoomed in to see the gap. Even though it saw much more use, the gap measured a more reasonable 0.0015" over 8" (0.038mm over 205mm).

The amount of dishing (or lack thereof), is interesting, and I was quite surprised. This stone is rather muddy, and felt a bit like my suehiro Rika #5000, which tends to dish in use. I searched many different offerings of waterstones, and based on the size, color, and character of this stone, I'm gonna guess that it's a King Hyper #1000. The Hyper stones have a harder composition and evidently added a different diamond-like abrasive to their mix, to be more effective when sharpening hard stainless steel knives.

I can't complain too much...... The stone was cheap, and it's a decent stone, works well, all that. An old, fine, natural stone? That it ain't.

Ironic, that as I am trying to get away from the synthetic stones, they somehow keep showing up. Swimming upstream.